The York compressor can be mounted vertically or horizontally to either side. However, if mounted horizontally, the manufacturer recommends that the suction port be on top. This is most likely due to the internal oiling system locating an oil return line from the crankshaft seal cavity into the air suction line. If you perform the oil system modification that plugs the oil return line to the suction port, then I’m not sure it matters which port is on top. Without that mod, orienting the compressor with the suction line on the bottom will result in excessive oil discharge in your compressed air. The York’s pulley can be rotated in either direction, so that’s not a concern when trying to join it with your existing belt system.

The standard York has an oil fill/check hole in the center of each side of the compressor body. Ideally, you should still be able to access this hole while the compressor is mounted so you don’t have to remove it to check/fill the oil. The York I got from a Ford had one of those holes plugged (that side was unreachable in the factory mounting location), so only the right side hole was usable. When fully filled, the factory specifies 8-12 ounces (237-355 mL) of oil. Since the factory intended about 2-4 ounces of that to be rotating through the A/C system during normal operation (see the oil system mod for details), you really only need about 8-10 ounces (237-296 mL) of oil inside the crankcase when used to pump air. The type of oil isn’t critical when used to pump air (w/o freon); regular old 10W30 or ATF will work fine (I use ATF in mine). A trigger-type oil squirt can seems to be the easiest way to add oil when necessary. To check the oil level, I recommend using a dip stick as described on page 7 of this section of the York service manual. It’s a PDF file, so you’ll need to have Adobe’s Acrobat Reader installed in order to view the file.

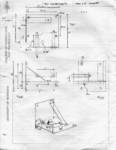

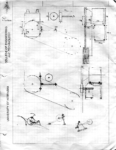

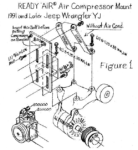

Mounting the York to an old Jeep with a 258 inline-6 or 304/360/401 V8 should be pretty easy, since this compressor was available from the factory. Just grab the OEM brackets from a similar engine with York A/C and you’re good to go. Mounting it on any other engine requires fabrication of a custom mounting bracket. Complete mounting brackets for newer Jeep engines used to (mid-1990’s) be available for $200+ from Therold Enterprises. Unfortunately, Therold went out of business. Someone else bought up all of his existing stock & jigs, but never got around to selling anything. The only option is now C U Off Road (formerly Brad Kilby) of OnBoardAir.Com, who sells pre-made mounting brackets for a variety of engines. They make quality stuff, and buying from him is a good option if you’ve got more money than time. Another option is to fabricate your own design. Craig Myers has a good design for mounting to his ’93 YJ 4-cyl that I believe is similar to what Therold sold at the time. I ended up with (essentially) two 6x6x3/16″ steel plates welded together to form a T. A diagram with mounting hole measurements is on page 1. Measurements of the alternator bracket, compressor, and pulleys without the compressor bracket is on page 2 (thanks to Robert Ameeti for finding me a good copy after 6 years). I later had to weld a triangular cross brace on the top of the bracket to limit vibration between the two large pieces of the bracket. The original welds were starting to crack from the constant engine vibration. This was one of my first welding jobs with my new on-board welder, so the welds were pretty ugly, but they’ve held up for 6 years now without breaking.

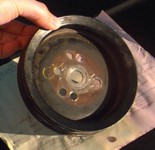

If your engine uses newer serpentine belts, you must somehow rig up a v-belt pulley to power the compressor’s v-belt pulley. Therold (now C U Off Road) sold a new alternator pulley for newer Jeeps with both serpentine and v-belt grooves. This seemed to be the route most people took back then, but the then-$40 price tag was a bit steep for me. I wandered around a junk yard until I found a pulley that would fit between my water pump pulley and the fan mount. I got one for $5 (I think it was from an ’80-ish Chevy Caprice — I forget exactly) that had 3 screw holes (my Jeep has four) and a 7/8″ center shaft hole (my Jeep’s was 5/8″). I took it to a local machinist who charged me $15 to narrow the center hole with a washer and drill a 4-hole bolt pattern to match that of my Jeep. I considered doing it myself, but a pulley spinning at 4000 RPM will cause nasty vibrations and eventually tear up your water pump if it’s not perfectly centered. My route was a bit more work, but I saved $20. The result required a 49-5/8″ v-belt (model 15490). The center of the belt originally had a little more play than I’d like, but a 49-1/8″ (15485) belt just wasn’t long enough. I made an idler pulley to keep tension on the belt once it stretched a little. Replacement belts that I bought seemed plenty tight by themselves, so I’ve since ditched the idler pulley. The mounting tabs can still be seen on my mounting bracket, though.

The first picture below shows the pulley as it came off the donor vehicle. The second picture shows the modifications that the machinist made to allow mounting to my YJ. The third photo shows it mounted in place.

If I were doing it again, I might just buy the stuff from Kilby rather than fabbing it myself. His way uses a $110 serpentine pulley plus a $20 plate that runs the compressor with the same serpentine belt that the rest of the engine uses. My set cost $20 for the re-machined pulley plus $40 for the bracket (got screwed there–he quoted me $25 initially). This cost $60 total, and I may have to add a sturdy, adjustable idler pulley to my compressor bracket if the belt turns out to be too loose.

Do you like this site?

Help me keep it going by throwing a few pennies my direction.

![]()

![]()

![]()

![]()

Links on this page to Amazon are part of an affiliate program that helps keep Jedi.com operational.

Thank you for your support!

like to use on 7.3 ford. any help for mounting using a york.

Hmm… I’m more of a Jeep guy, and have never taken a good look at a 7.3L Ford engine. Fortunately, google shows several options, including this one:

https://www.ford-trucks.com/forums/1378936-york-210-air-compressor-on-a-7-3-a.html